When copper was discovered some 10,000 years ago, its potentials were initially belittled, so much so that man decided to mix it with other metals, such as tin and zinc, in the hopes of creating much stronger metals. True enough, they were able to produce two of the most prominent metals of all time—bronze and brass. In fact, one of them—bronze—became so widely used that an entire era was named after it. But why are they so popular? Well, it has to do with their many beneficial properties.

Bronze: Not Always the Third Best

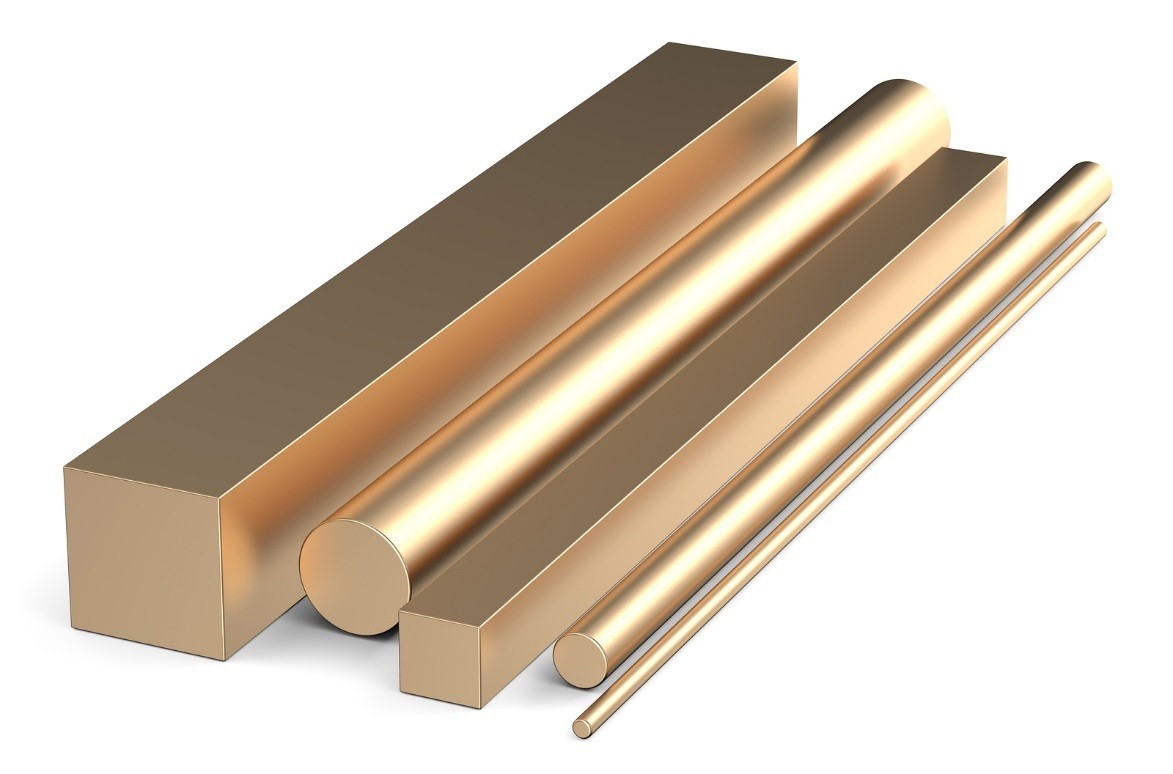

To produce bronze, you only have to mix copper and tin. Some other metals, such as aluminum, manganese, and nickel and non-metals, such as arsenic and phosphorus, are also sometimes added but only in miniscule amounts. The kind and quality of bronze produced greatly depends on the amount of each metal used in the alloy. Typical bronze has about 12 percent tin, 1 to 3 percent of other metals and metalloids, and the rest copper.

Most bronzes have a distinct metallic brown color, although manufactured bronzes usually have a pinkish finish. They are brittle but also incredibly ductile, which means they can be hammered thin or stretched into wire without breaking. Bronze shows low friction when rubbed against other metals, making a perfect material for applications that involve the use of flammable or explosive materials. This metal also has a discrete rustic appearance that is valued in architecture and in the art world. Surprisingly, even with all these amazing benefits, bronze is always associated with “third place”, next only to gold and silver.

Brass: The Unassuming Great

Copper is no doubt a flexible metal. It can be mixed with almost anything, and alloys with useful properties would emerge. One of the most prized alloys of copper is brass, a combination of copper and zinc. Like bronze, other metals and non-metals are welcome to the mix to produce even higher-quality brasses. The proportions of copper and zinc may also be varied to produce brasses of varying properties.

Brass has higher malleability than bronze mainly because it has lower melting point. In effect, brass is extremely easy to cast and work with. This metal is also non-ferromagnetic, which means it cannot be magnetized along with iron and other ferromagnetic metals. This makes collecting brass scrap easier and faster. While brass is often used for making musical instruments, it is also extensively used in water systems because of its antimicrobial properties.

These are only some of the amazing beneficial properties of copper alloy that you need to know, especially if your future project requires a good deal of metals. Whether you need a bronze bar or a brass angle to put in your design, and whether it’s for aesthetic or structural purposes, copper alloys really could meet if not exceed your expectations. To make sure you’ll get the best metal products, though, choose a trusted supplier like Rotax Metals.

Sources:

What Is Bronze? Definition, Composition and Properties, thoughtco.com

Copper: Properties and Applications, copperalliance.org.uk

Ductile Definition and Examples, thoughtco.com