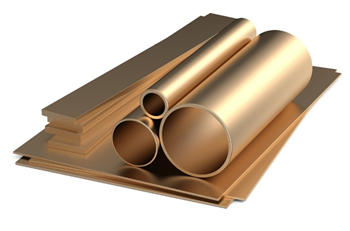

The use of copper as an adornment is an ancient practice that comes to modern designers and architects from the Greeks and Romans. Through the creation of alloys such as bronze and brass, the beauty of copper can be combined with the structural strength of other metals to create sheet metal panels and square tube. These alloys offer tremendous opportunities for unique treatments including polishing and chemical etching that can generate a one of a kind finish on objects and design elements that will last for years to come.

The addition of custom treated sheet metal panels used as backsplash, wainscoting, wall panels and other décor features requires access to the in depth knowledge of local sheet metal suppliers. Particularly when working with metals such as brass and bronze, the handling of the metal by the supplier can have a large impact on how it will look in any application. Additionally, it is important to note that bronze sheet metal often shows rings on the surface once it’s polished. This unique feature of this durable material could provide yet another custom touch to the final product.

Brass and bronze are particularly versatile metals due to their corrosion resistant qualities. In addition, the copper included in the alloys of brass and bronze offer many options for polished finishes. These metals offer the chance to connect the outdoors to the inside of a structure via the use of chemical treatments and etchings. If a particular design project calls for creating a visual connection between the exterior of the structure and the interior space, chemically treated panels of brass or bronze can create a striking visual effect for many years to come.

Brass and bronze square metal tubing offer structural strength and visual appeal. In light fixtures, outdoor furniture and other applications that need water tolerance and corrosion resistance, alloys of brass and bronze offer designers and architects the opportunity to create open structures of great strength and beauty, no matter the atmospheric conditions. Options for designers and architects are further enhanced by the unique features of each of these two alloys. While brass is primarily a combination of copper and zinc, offering plenty of polishing options for sheen and bright reflection, bronze is primarily a combination of copper and tin, producing a duller metal tone. Depending on the design choices and application requirements, these differences in tone can offer great options for the designer’s eye.

Sources:

Historic Preservation – Technical Procedures, gsa.gov